All production-relevant processes are documented in detail at Sensoplast.

The existing quality management system is coordinated with these process workflows.

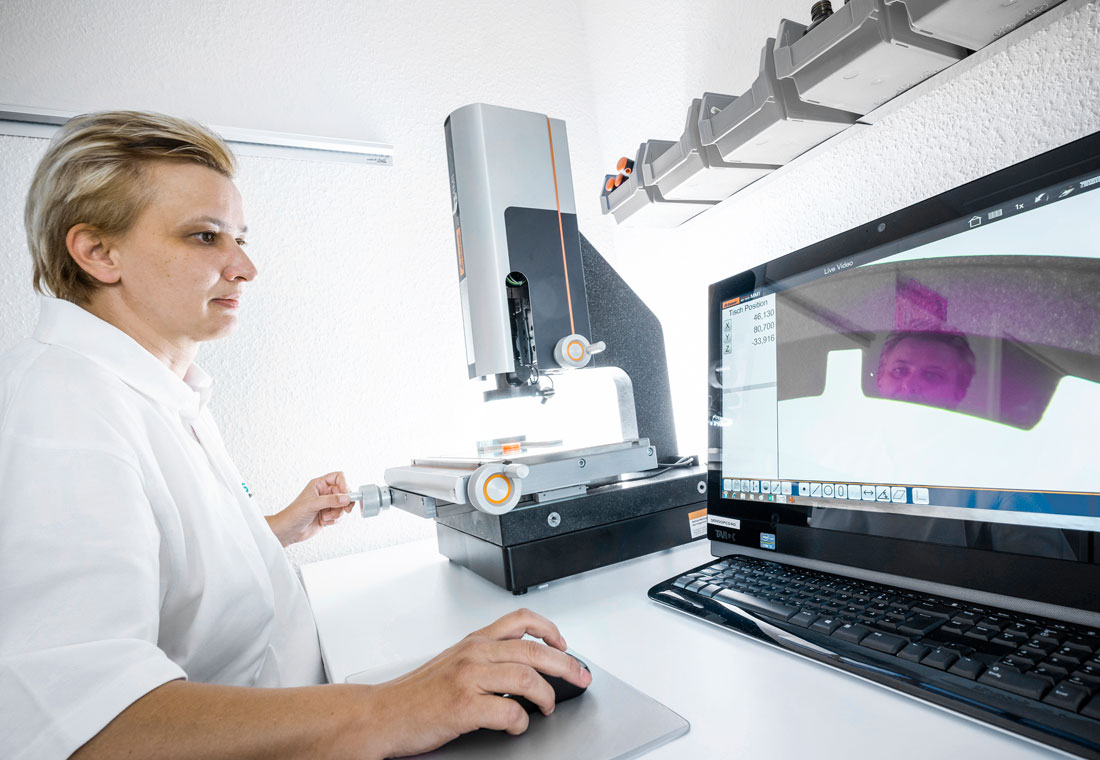

Seamless batch tracking of produced components is guaranteed throughout the whole value chain. All components and end products are carefully inspected by our Quality Assurance department at different points in the production process. They comply with the high quality requirements for pharmaceutical primary packaging.

Production, assembly and packaging are conducted under the most stringent hygienic conditions. When assessing quality, Sensoplast is guided by the recommendations of the World Health Organisation (WHO), the pharmaceutical industry, Good Manufacturing Practice (GMP) and by the relevant defect evaluation lists for injection moulded plastic parts: Closures, liners, dosing aids (droppers etc.) comply with the publications by ECV Editio Cantor Verlag für Medizin and Naturwissenschaften GmbH, Aulendorf, Germany.

Our test results for finished products are regularly documented and are available on request in the form of a comprehensive quality certificate.

The Sensoplast quality management system is certified according to ISO 9001 and ISO 15378.

Our predominantly international customers can always be certain that our primary packaging products are manufactured, assembled and packed to high procedural and hygienic standards under controlled quality conditions.

Download certificates and further documents